Wabtec

Designing Scalable Systems through Deep UX Research

TL;DR

Role: Lead Researcher on intermodal yard digitization at GE Transportation (now Wabtec)

Focus: Clarity and efficiency in freight operations tools across yard supervisors, maintenance crews, and control center operators

Methods: Field ethnography, stakeholder interviews, heuristic evaluations, usability testing, co-design workshops

Impact: Strategic UX recommendations enabled redesign of a mission-critical logistics platform, later sold to BNSF and deployed across intermodal yards

Project Context

GE Transportation was building a digital platform to orchestrate intermodal freight operations across U.S. rail yards. The system aimed to coordinate decisions between yard supervisors, control center dispatchers, crane operators, and maintenance teams — each using different tools, processes, and mental models.

I joined the team to lead UX research across the platform’s early development phase. The goal: identify friction points across roles, simplify workflows, and inform a design system that could scale across multiple yards and job functions.

Challenge

Designing for intermodal yard operations meant tackling complexity on multiple levels, across roles, tools, and physical spaces. Supervisors made dock and crane assignments in real time with limited system visibility. Control center dispatchers coordinated incoming and outgoing rail traffic while juggling radio updates and spreadsheet logs. Maintenance and equipment teams worked with outdated or siloed tools, leading to delays, redundant checks, and frequent miscommunication. This complexity surfaced several UX challenges:

Cognitive overload: Disconnected interfaces forced users to mentally stitch data across tools and channels

Fragmented mental models: Each role held a different understanding of real-time yard state and priorities

Analog workarounds: Despite ongoing digitization efforts, paper logs and whiteboards still served as primary coordination tools

Unreliable task handoffs: Without shared digital triggers, downstream actions were often mistimed or incomplete

The risk was clear: without a deep understanding of real-world workflows, the platform could digitise confusion rather than eliminate it.

Immersive Field Visits (Shot on GoPro)

Screen Operation Environment

User Archetype

My Role & Research Approach

As the embedded UX researcher on this 2.5-year transformation project, I worked closely with cross-functional teams to align fragmented rail yard workflows, surface critical user pain points, and enable a product strategy grounded in field realities. My approach combined deep ethnography, ecosystem mapping, evaluative testing, and stakeholder alignment. Key research activities included:

Field Ethnography & Contextual Inquiry: Shadowed dispatchers, planners, gate agents, and yard staff across intermodal yards in the U.S. to document real-world behaviors, constraints, and decision-making patterns.

Journey Mapping & Role Swimlanes: Created detailed task flows and role-based interaction diagrams to capture overlaps, redundancies, and friction across tools and personas (including offline coordination).

Service Blueprinting & Systems Modeling: Mapped interdependencies between digital tools, planning logic, and physical yard movement to reveal gaps in visibility, sequencing, and decision triggers.

Co-Design Workshops & Cross-Functional Alignment: Facilitated working sessions with product, operations, and engineering teams to identify mismatches between tooling and workflow, and co-prioritize redesign opportunities.

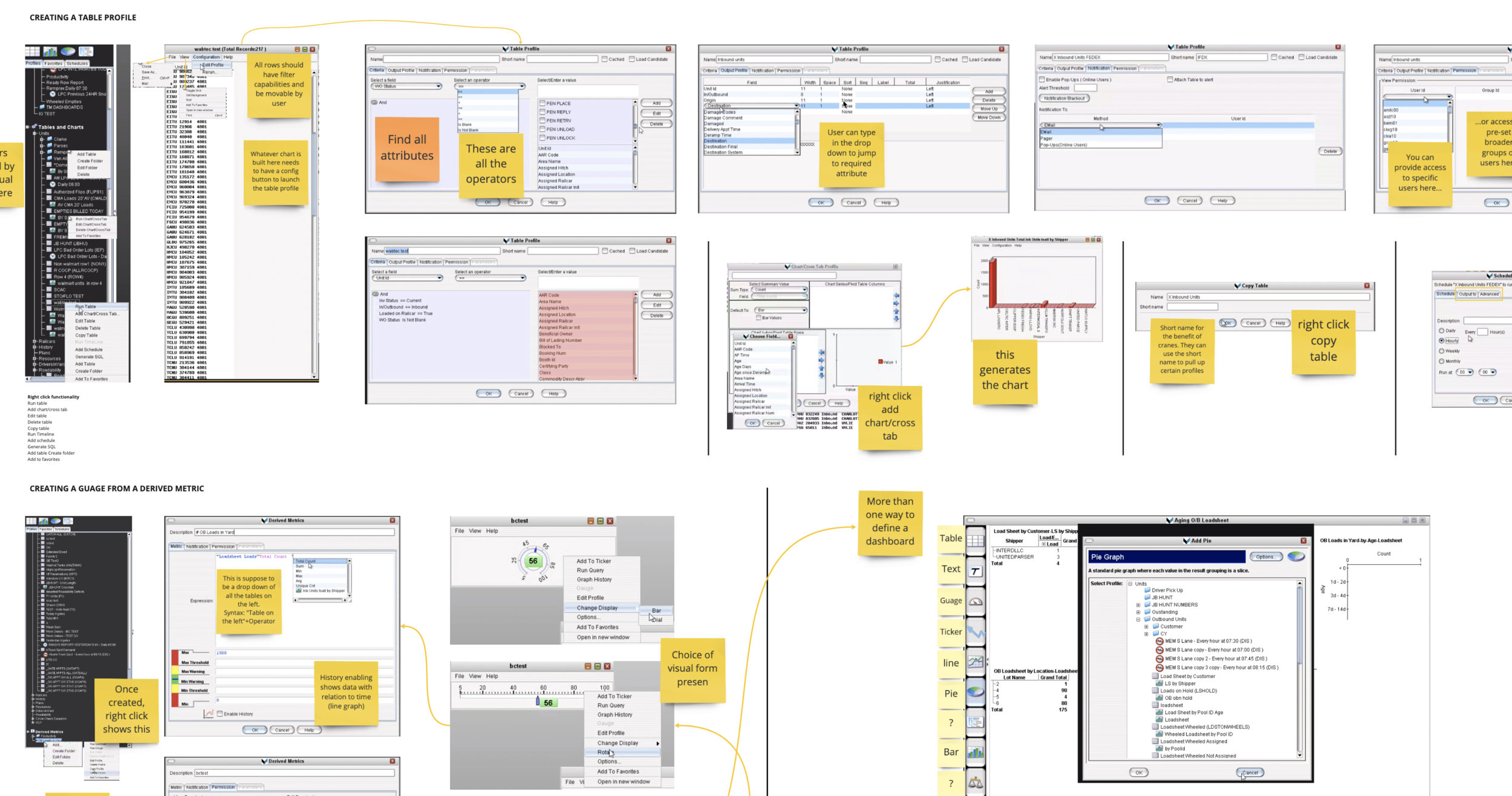

Heuristic Evaluation & Usability Audits: Conducted expert reviews and interface audits of legacy tools, identifying usability issues, terminology inconsistencies, and inefficiencies in navigation or task flow.

SUS Benchmarking & Feedback Synthesis: Aggregated usability scores, testing feedback, and stakeholder narratives to deliver a compelling case for roadmap-level product and service design improvements.

This research formed the backbone of design decisions across multiple touchpoints, clarifying planning flows, reducing system toggling, and helping secure buy-in for large-scale operational tooling overhauls.

Heuristics Evaluation

Usability Benchmarking

Cross-functional Workshops

Research Insights & Outcomes

Through fieldwork, heuristic audits, and co-creation sessions, I uncovered systemic inefficiencies across GE’s intermodal yard operations and delivered research that directly shaped product decisions and stakeholder alignment.

Key Insights

Redundant Workflows Across Roles: Yard planners, supervisors, and gate agents duplicated tasks like equipment verification using disconnected tools. This redundancy caused delays, rework, and increased operational overhead.

Mismatched Mental Models: Each role had a different interpretation of yard state and task progress. Without shared visibility, teams operated on assumptions, not real-time data, resulting in frequent coordination breakdowns.

Low Tool Adoption in Critical Moments: Operators abandoned the system during peak stress. They reverted to analog methods like radios and whiteboards, signaling critical UX and reliability issues.

Information Overload, Poor Prioritization: The interface presented dense, non-contextual data. Users lacked confidence in what to focus on, slowing task execution and reducing decision accuracy.

Strategic Impact

Influenced Product Direction for Yard Visibility Tools: My findings led to the proposal of a role-based dashboard with filtered views tailored to supervisors, planners, and gate staff. This feature was prioritized for pilot release, directly addressing the fragmentation I uncovered.

Reduced Task Duplication through System Redesign: By identifying shared workflows, I drove a consolidation effort that merged overlapping verification processes into a unified system path—saving operators an estimated 1–2 hours daily across shifts.

Service Blueprint Adopted for Cross-Team Planning: A detailed blueprint I created became a strategic artifact used by both product and operations teams to visualise role handoffs and identify system blind spots. It was adopted as a planning tool for future iterations.

Elevated UX to Leadership Strategy: Research outcomes were presented to senior operations leadership as justification for investing in a systems-level overhaul. This led to cross-functional alignment and new funding for tool modernization.

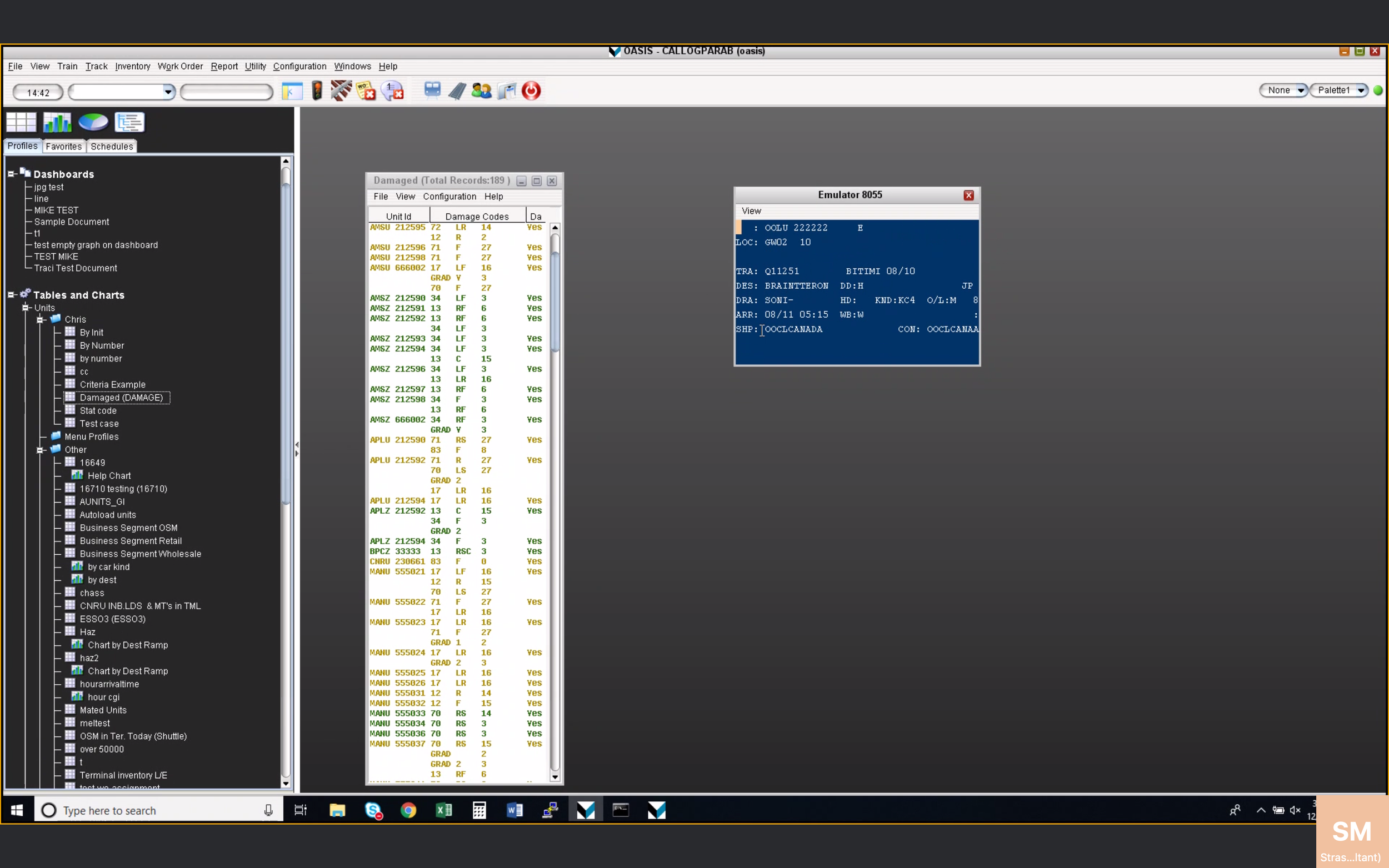

Legacy Platform

Final updated platform homepage after 5 iterations

Updated Product Branding